Tunnel Construction and know its methods.

Tunnel Construction is a below-ground transit provided under the earth’s surface or water. Mostly in this cases tunnel construction is costly, but it saves time and provides comfort. The large unearthing of soil or rock and many more items are necessary for tunnel construction. With the obtainable of modern appliances, earthing and back and fill has become easy. Tunnels are getting in use for roadways, railways and even as water waterways also. In many cities, unearthing metro rail networks work inside a tunnel.

Methods of Tunnel construction:

Cut and Cover Method:

Its construction basically gets in use to build the glib tunnels. This method includes a trench cut in the soil which gets cover by some of the holds up which has the ability to carry the load on it. This cutting gets done by two methods and they are:

- Bottom-up method – In this method, the tunnel is below the ground, under the surface using the ground support.

- Top-down method – In this, the side support walls get construct first. After the slurry walling method is complete, the roof gets discover on the top of the walls and the earth is carrying out. After that, the base slab is constructed. Most of the below-ground metro rail stations are constructed using cut and cover method.

Advertisement

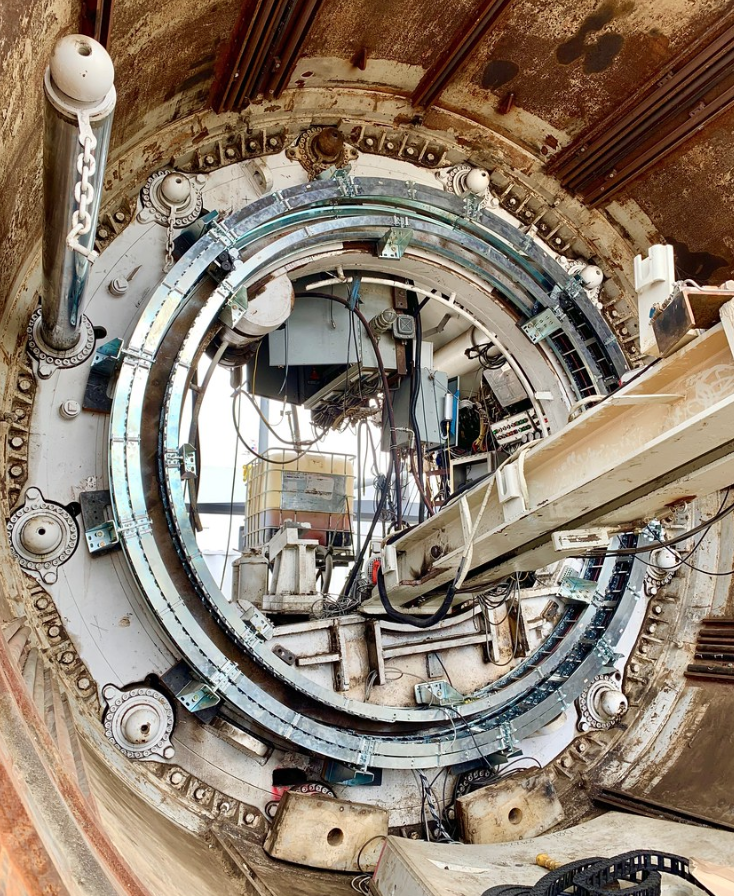

Bored Tunnel Method:

The bored Tunnel method is current technology. In this case, tunnel boring machines get in use for mechanical work and make the whole tunneling process easier. It is also a fast process and a good method to build in high traffic areas. Tunnels boring machines are present in different types acceptable for different land conditions.

Machines can get use in conditions such as below the water floor and more. A special pressure section provides for TBM to work in below water floor conditions. The workers don’t get allow to enter the section excluding for repair works. Proper care is to be taken when the TBM is in working condition. The difficult part of TBM is its heavyweight. That is why transportation is difficult and expensive.

Pipe Jacking Method:

This method employs to construct the under structures like roadways, railways, and many more. In this method, pipes are operating into the below-ground using hydraulic banners. The maximum size of tunnels that allow is the 3.2-meter diameter.

Box Jacking Method:

Box jacking method is like the pipe jacking method, but in this case, as an alternative of pipes, there are boxes that get drove into the soil. A cutting head is provided at the front side of the box. The excavated matter gets collect inside the box. The larger size tunnels can be excavate using the box jacks up to 20 meters.